| Plastics News |

Low fogging adhesive tapes showcased during NPE show in Orlando

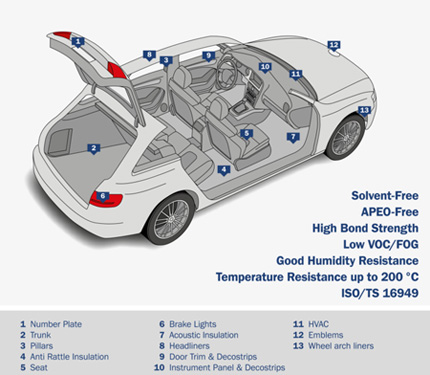

February, 18, 2015 - Headquartered in Switzerland and with production in Germany, ATP adhesive systems (Booth S30084, South Hall, at NPE2015) specialise in the development and production of solvent- free, speciality pressure sensitive and heat activated tapes and films for the automotive industry. ATP announced a bespoke range of low emission adhesive tapes and films which are capable to bond a wide variety of materials used in the production of automobile components including:

Derek Bamborough, Manager of Application Technology and Development, explained ‘that the target of the new development was to fulfil the widest spectrum of bonding performance whilst realising the lowest possible adhesive emissions Head of Applications Support, Gerhard Fuchs, explained, ‘based on our bespoke adhesives we are able to offer our customers a choice of carrier, liner and tape dimension and where necessary, customise products to suit their individual requirements’. ATP has coating capability up to 2200mm in width and the versatility to produce a wide range of toll and custom coatings. Typical substrates bonded by ATP’s adhesives include:

Furthermore, ATP announced in July, 2014 a significant new investment of approx. €20 million for its production facility in Mihla / Buchenau. This investment includes the construction of a production and warehousing facility with a new 12’000m² building together with 860 m² office complex. The central focus point of the new factory will be the new 70 m long, state-of-the-art coating line with clean-air manufacturing, allowing ATP to offer adhesive tapes with exceptionally high quality optical appearance. Managing Director Daniel Heini explained ‘the new production facility will create between 50-60 new jobs for highly trained staff, in addition ATP will continue offering training places for job-starters.’ Source: ATP |