| Plastics News |

BASF develops polyamide grades for sensitive automotive electronics

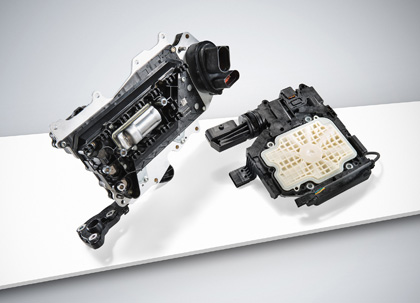

March, 8, 2016 - For reliable micro-electronics in sensitive automotive applications such as control units and sensors, BASF has now developed a portfolio of various polyamide 6 and 66 grades that help prevent damage to circuits by electric corrosion, the company claims. The different Ultramid® EQ grades (EQ = electronic quality) are extremely pure, which means they have hardly any electrically active or corrosion-generating contents, yet still offer good resistance to heat aging, according to BASF. They are subject to special quality tests that cover raw material selection, the production process, and the analysis of the halogen content. Available globally, the portfolio consists of uncolored and black grades with glass fiber contents of 30 and 35 percent, which are also laser-markable. Ultramid® EQ has already proven itself in a range of applications under harsh conditions. Electronic assemblies in modern transmission control units or safety-related applications such as airbag and anti-lock systems are becoming ever more compact and complex. They are also often exposed to high ambient temperatures and aggressive media such as oil. The delicate circuits are more frequently connected to semi-conductors via thin wires which is known as wire bonding. In such surroundings, disruptive effects such as corrosion, ion migration, electrolyte formation, and creep currents can arise and in extreme cases cause entire assemblies to fail. Plastics for housings and components have to be equipped in such a way that they do not react with the metals involved and thus prevent electronic failure. All Ultramid® EQ grades have an organic heat stabilizer with a very low halogen content of less than 1 ppm. This prevents halogens like iodine or bromine from damaging metal wiring, ions from reacting with the metals, and undesired electric currents from arising, explains BASF. In addition to the specified formula and complex production process, BASF claims that all Ultramid® EQ charges are checked carefully. This ensures that the manufacturing process does not introduce any halogen contamination to the material. The relevant certificate is provided to customers if desired. The new Ultramid® EQ portfolio is also well-suited for use in electric and hybrid vehicles with elevated AC and DC voltages. Source: BASF

|