| Plastics News |

Arkema showcases its offering of advanced materials for composites at JEC World 2018

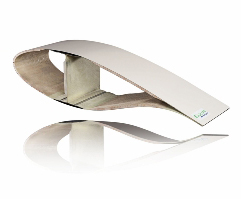

The result of Arkema’s research and development, Elium® is the only liquid thermoplastic resin on the market that can be processed with the same manufacturing methods as a thermoset liquid resin, the company claims.. First showcased at JEC World 2016 in the form of a 6.50 meter prototype sailboat, the Elium® resin has since seen many developments and afforded new growth opportunities, in particular in wind power and construction. A choice material for the wind power market Following the manufacture, in 2017, of a 9 meter-long demonstration wind turbine blade from Elium® thermoplastic resin, compatible with existing turbine blade manufacturing technologies, a further milestone has now been reached in the development of this resin in the wind power market. A 25 meter-long blade has been manufactured with the company Plastinov, which specializes in infusion molds and processes. This process has helped validate the feasibility of producing these components on an industrial scale. This project is part of the Effiwind program of the CANOE innovation platform which aims to fit the oldest wind turbines with new and more efficient 2 meter longer blades. The next stage of this project is the certification of the 25 meter-long blade before the commissioning for a series of tests of a wind turbine fitted with these new blades. "The benefit of using longer blades, without changing the base or the tower of the wind turbine, is that it helps raise energy production by around 15%, thanks to optimized operation in medium wind conditions, which tend to be the prevailing conditions for these installations", says Guillaume Clédat, Elium® Product Manager The 9 meter-long demonstration blade made from the Elium® thermoplastic resin on the IACMI (Institute for Advanced Composites Manufacturing Innovation) site in the United States has been nominated for a JEC Innovation Award 2018 in the “Sustainable Development” category. Lightweighting in construction - Pultrusion technology with Elium® resin The Elium® thermoplastic resin can be processed using a variety of technologies, including pultrusion. In partnership with the IRT M2P Technological Research Institute in Metz, Arkema has developed optimized grades for this specific converting process that helps produce glassfiber or carbon fiber reinforced profiles. These new composite products open up promising prospects in construction, with two target applications in particular, according to Arkema:

Recyclability In 2017, Arkema´s R&D teams were heavily involved in developing the recycling process for composite parts made from the Elium® resin via depolymerization: the parts are ground down coarsely; the Elium® resin is then heat-depolymerized so that it can be recovered and purified into a resin with the same properties as the virgin resin. The remaining carbon or glass fibers can be reused. Source: Arkema |

February, 20, 2018 - Arkema will showcase at JEC 2018, from March, 6 to 8, its unique range of advanced materials and solutions to meet growing demand for lightweighting structures in the transportation, wind power and construction sectors. With its Elium® resin, the Group offers an alternative to the challenging equation that is the recyclability of these materials.

February, 20, 2018 - Arkema will showcase at JEC 2018, from March, 6 to 8, its unique range of advanced materials and solutions to meet growing demand for lightweighting structures in the transportation, wind power and construction sectors. With its Elium® resin, the Group offers an alternative to the challenging equation that is the recyclability of these materials.