| Plastics News |

Nordson introduces innovation die design for multi-layer fluid coating

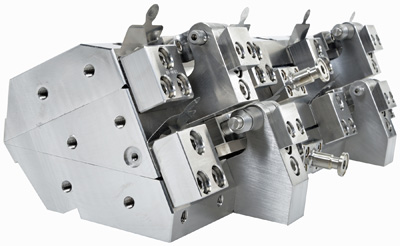

March 6, 2017: A new, patent-pending design for dual- or multi-layer versions of Nordson Corporation’s Premier™ and Ultracoat™ fluid coating dies makes it easier to achieve parallel alignment of the lip faces, the company claims. The alignment is critical for maintaining uniform, defect-free coating and preventing impingement of the lips against the roll. In the standard design for Premier fixed-lip and Ultracoat adjustable-lip slot dies, operators make changes to the die gap—and thus the wet film thickness of the coating—by inserting thin metal strips, or shims, between the die bodies, then using more shims at the rear of the die to eliminate the resulting offset of the lip faces and ensure that they are once again in the same plane. Until now, use of these “offset shims” has been more complicated in multi-layer dies, requiring calculations to determine which shim thickness most closely achieves lip face parallelism. The new design makes such calculation unnecessary, ensures a more precise lip face alignment, and prevents human error, Nordson says. Nordson has achieved this improvement by reconfiguring the die bodies of multi-layer Premier (photo) and Ultracoat systems so that the offset blocks, where the offset shims are inserted, are now in the same plane as the lip face (see schematic). As in the past, body shims and offset shims are available in thicknesses ranging up to 0.060 in. (-1.524 mm). With the new design, the accuracy of the offset adjustment is independent of body shim thickness. “Nordson’s new design for multi-layer dies makes it easier for web converters to achieve the substantial cost savings and productivity benefits obtained by applying multiple fluids in a single pass,” said Keith Wheeler, business unit director for fluid coating systems. “Besides being more accurate and user-friendly, the new design for multi-layer dies eliminates the cause of lip misalignment and helps to prevent the costly damage to both die and roll that can result from simple human error in calculating the lip offset.” Replacing multiple coating passes with a single product run means an increase in output and a reduction in machine use, energy consumption, and scrap. Additional cost savings result from control over the thickness of each layer, preventing over-use of expensive high-functionality fluids. At the same time, the converter has the flexibility of returning to single-layer production simply by closing the feed valve to the flow channel that is not in use. Source: Nordson

|