| Plastics News |

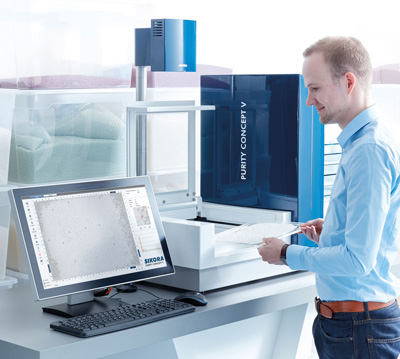

Sikora makes debut of its optical offline inspection and analysis system for sample testing of plastic material at Fakuma

Sikora will be displaying at Fakuma in Friedrichshafen from October 16-20, 2018 its innovative measuring, control, inspection, analysis and sorting devices. At the Sikora booth, visitors can expect a comprehensive portfolio of systems for quality control and process optimization for the hose and tube as well as plastics industries. Sikora will present innovative systems for quality control during the extrusion of hoses and tubes as well as for the inspection, sorting and analysis of plastic materials. For the first time, Sikora will present the Purity Concept V at Fakuma, an optical offline inspection and analysis system for sample testing or incoming goods inspection of plastic material. Material samples, placed on a tray, are moved through the inspection area. Within seconds, the material is inspected automatically by a color camera and a projector marks the contaminated material directly on the sample tray. By analyzing the recorded images, contamination on the surface of transparent, diffuse and colored material are automatically detected, visualized and evaluated, Sikora says. A clear allocation of the contamination and follow-up inspection are possible at any time. The manufacturer claims that its system is more accurate, more reproducible and more reliable than human eye and manual light table, and determines the size of contamination, and thus, contributes significantly to quality control and process optimization. Furthermore, Sikora offers systems for offline inspection and analysis based on X-ray technology that detect and analyze contamination inside of plastic materials. The Purity Concept V for optical offline inspection and analysis of plastic materials celebrates its premiere at Fakuma. By analyzing the recorded images, contamination such as “black specks” inside transparent pellets as well as on the surface of opaque and colored material are automatically detected, visualized and evaluated, Sikora says. For online inspection and sorting of plastic material, the Purity Scanner Advanced is the appropriate equipment. The system combines X-ray with optical technology and detects contamination inside plastic pellets as well as on their surface. The company uses the adaptive camera concept, where up to three optical cameras are used, depending on the expected contamination and application. For example, an X-ray camera detects metallic contamination inside pellets, optical cameras identify yellow discolorations as well as “black specks” inside transparent and opaque pellets, whereas color deviations are detected by color cameras. Contaminated pellets are sorted out automatically. Sikora says that the interaction of online and offline inspection, sorting and analysis enables, for example, complete 100 % quality control as well as sample testing of the material cleanliness and the establishment of a database in order to improve processes and to avoid further contamination. For 100 % quality control during the extrusion of pipes, Sikora presents the Centerwave 6000. Millimeter waves technology y measures the diameter, ovality, wall thickness and the sagging of the product. The measuring principle does not require any coupling media, is not influenced by temperature or the plastic material and measures precisely without the need of any calibration, Sikora claims. A presetting of the product parameters is not required. The X-RAY 6000 PRO is a further highlight for measuring the wall thickness, eccentricity, the inner and outer diameter and the ovality of hoses and tubes. Hereby, the thickness of up to three different material layers is measured. Furthermore, Sikora presents diameter measuring systems of the LASER Series 2000 as well as LASER Series 6000, which also offer lump detection in addition to diameter measurement. Sikora’s presentation in Friedrichshafen is completed by reliable lump detectors that detect irregularities on the product surface. Source: Sikora

|