| Plastics News |

Orion S.A. to showcase innovations in conductive additives at 2024 IWCS Cable & Connectivity Industry Forum

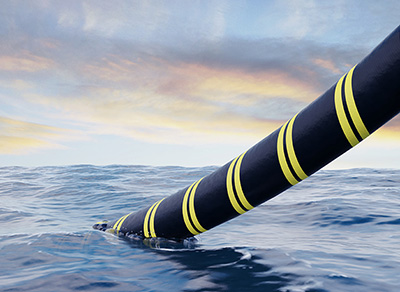

August, 15, 2024 - At the IWCS 2024 Cable & Connectivity Industry Forum, global specialty chemicals company Orion S.A. will showcase its conductive additive portfolio, designed for wire and cable and other conductive applications. Orion (Booth #206) will highlight developments underway, including its latest innovation Printex kappa 60 conductive additive, designed for conductive polymer compounds and a strong choice for wire-and-cable applications. The IWCS 2024 Cable & Connectivity Industry Forum will take place Oct. 14–17, 2024, in New Providence, Rhode Island. Orion says conductive additives increase cable service life by delivering high product purity, desired conductivities, superior surface smoothness and UV protection to medium-voltage (MV) distribution and high-voltage (HV) transmission cables. “Over time, we’ve optimized the colloidal properties of legacy conductive additives to ensure excellent dispersibility and product cleanliness in our newest grades plus those in development,” said Kevin Milks, Orion marketing manager for polymers and special applications. Printex kappa 60 conductive additive meets the dispersion and cleanliness requirements for wire and cable applications, Orion claims. In separate product developments, two new circular additives produced from end-of-life tire pyrolysis oil match the performance of regular, fossil-based specialty carbon black used in cable jacketing. Plus, Orion says its premium, acetylene-based Printex kappa 100 Beads, launched at the IWCS 2023 Cable & Connectivity Industry Forum, offer dispersibility, high cleanliness, purity and conductivity, making them ideal for use in high-voltage (HV) electric transmission cables. To increase acetylene black availability, Orion on April 9 broke ground on a plant in La Porte, Texas, that will be the only facility in the U.S. producing acetylene-based conductive additives for wire and cable, lithium-ion battery and other applications vital for the global shift to electrification. The facility is expected to begin operation in the second quarter of 2025. “We look forward to providing the North American wire-and-cable industry with a consistent supply of domestically produced acetylene-based conductive additives,” said Jennifer S. Stroh, Ph.D., Orion vice president of sales and marketing Americas. “We also look forward to customizing At the 2024 IWCS Industry Forum, Scott Brewer, senior technical market manager, will present “Carbon black and conductivity in medium and high voltage cables” as part of the Materials technical track. He will present Tuesday, Oct. 15 at 3:15 p.m. Orion S.A. is a leading global supplier of carbon black, a solid form of carbon produced as powder or pellets. The material is made to customers’ exacting specifications for tires, coatings, ink, batteries, plastics and numerous other specialty, high-performance applications. Carbon black is used to tint, colorize, provide reinforcement, conduct electricity, increase durability and add UV protection. Orion has four innovation centers and produces carbon black at 15 plants worldwide, offering a variety of production processes in the industry. The company’s corporate lineage goes back more than 160 years to Germany, where it operates the world’s longest-running carbon black plant. Source: Orion

|